The Key Milestones of Singapore’s Safety Case Regime are summarized as below, based on the information available to SafetyCase.SG. Your feedback is most welcome to help update it.

May 2013: MHI Study Mission

In May 2013, MOM led a multi-agency study mission with representation fromMOM, SCDF, NEA, EDB, JTC, WSH Council and the Singapore Chemical Industry Council(SCIC) to study how leading WSH countries such as the United Kingdom,Germany and the Netherlands manage MHIs.

Mar 2014: Inter-Agency Taskforce for MHI(IAT-MHI) formed

Following the study mission, in March 2014, MOM set up an Inter-Agency Taskforce to review and enhance the existing MHI regulatory framework, in order to enable better oversight of SHE risks in the MHI sector and to be line with the international best practices.

Dec 2014: Recommendation of Safety Case Regime and National MHI Regulatory Office(NMRO)

In Dec 2014, IAT-MHI completed the above mentioned review and recommended to introduce Safety Case Regime for MHIs and to establish the National MHI Regulatory Office(NMRO).

Mar 2015: Announcement of the introduciton of WSH(MHI) Regulations in Parliament

On 9 Mar 2015, MOM’s Senior Parliamentary Secretary, Mr Hawazi Daipi, announced in Parliament the introduction of WSH (MHI) Regulations and the establishment of NMRO.

Jun 2015: First meeting of Safety Case Joint Work Group(SC JWG) conducted

In the middle of 2015, with the help of SCIC, the Safety Case Joint Work Group was established, with representatives from Government (MOM,NEA &SCDF) and from Industries (SRC, ExxonMobil and Shell).

On 5 th June 2015, its first meeting was conducted.

The objective of SC JWG is to

- support enhancement of Process Safety Regulatory Framework in Singapore by developing implementation proposals and technical guide for Safety Case Regime;

- and coordinate with SRMC/SCIC QRA Work Group to ensure revised QRA Guidelines are fit for adoption into Safety Case Regime.

Nov 2015: WSH Institute Visiting Expert Series:Safety Case – The Way Forward

This WSH Institute Visiting Expert Series (VES) was held in collaboration with the Ministry of Manpower (MOM) and Institute of Chemical and Engineering Sciences (ICES) of A*Star. The half day session entitled Safety Case – The Way Forward held on 27 November was attended by around 140 participants from chemical processing, oil and petrochemical industries, pharmaceutical and wafer fabrication plants.

Jan 2016: Public Consultation on the proposed WSH(MHI) Regulations

In January 2016, the Ministry of Manpower (MOM) invited the public to provide feedback on the proposed Workplace Safety and Health (Major Hazard Installations) Regulations (MHI Regulations). The objective of the proposed Regulations is to implement a Safety Case regime and streamline existing Workplace Safety and Health (WSH) regulatory requirements for MHIs.

Feb 2016: MHI Leadership Forum

In Feb 2016, the MHI Leadership Forum was held. More supporting information about this forum is needed.

Sep 2016: MHD formed

In Sep 2016, the Major Hazards Department (MHD) is a joint-government department led by MOM and comprises officers from NEA, SCDF and MOM.

Its objective is to be a single regulatory front for:

- Quantitative Risk Assessment (QRA) submissions.

- Safety Case assessment and site verifications.

- Investigations into MHI incidents involving multi-agency coordination work among NEA, SCDF and MOM.

Sep 2016: Enactment of WSH(MHI) Regulations

In Sep 2016, WSH(MHI) regulations was enacted. And it’s targeted to take effect after one year. (Supporting source needed)

Oct 2016: MHI Symposium

Major Hazards Department (MHD), in conjunction with the Workplace Safety and Health Institute (WSH Institute) and A*STAR’s Institute of Chemical and Engineering Sciences (ICES), organised the Major Hazard Installations (MHI) Symposium. The Symposium was held on 20 Oct 2016 at the JTC Summit Theatrette to update MHIs on the impending Safety Case regime. More than 200 participants, comprising company leaders and senior management, from over 80 MHIs attended the Symposium.

Oct 2016: Safety Case Technical Guide and Draft Safety Case Assessment Guide Issued

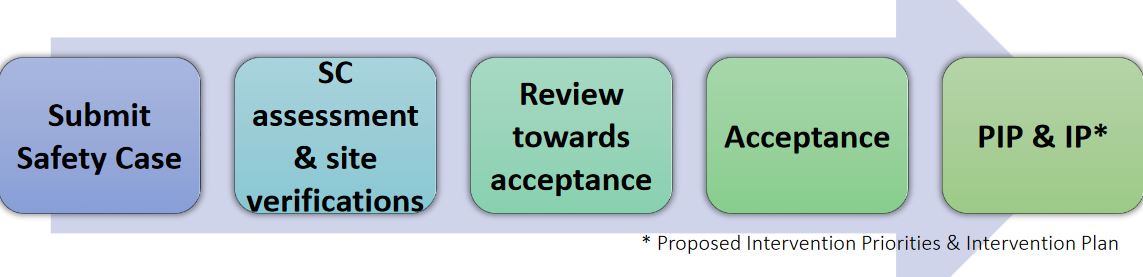

Safety Case Technical Guide describes how a Safety Case shall be structured and presented by MHIs to the Major Hazards Department (MHD) to meet the WSH (MHI) Regulations.

Safety Case assessment guide sets out the principles and approach used by MHD in its assessment of Safety Cases.

The technical and assessment guides were co-developed with the industry under the Joint Industry-Government Work Group, which was supported by the Singapore Chemical Industry Council (SCIC).

Oct/Nov 2016: Commencement of Safety Case Clinic

Safety Case Clinic commenced after MHI Symposium.

The objective of Safety Case Clinic is to help MHIs in their preparations for pre-receipt and Safety Case submission, MHD will conduct Safety Case clinics for MHIs to seek consultation on safety case matters.

Nov 2016: PEB Briefing on Registration as Professional Engineer in Chemical Engineering

PEB held a briefing on the registration of professional engineers (PE) in chemical engineering that would commence with effect from 1 Jan 2017. The briefing was held at Level 6 Auditorium at JEM Building on 28 November 2016. Members and staff from Institution of Engineers Singapore (IES), Association of Consulting Engineers Singapore (ACES), Society of Loss Prevention (SLP), IChemE in Singapore, Singapore Chemical Industry Council (SICC), local universities and Major Hazard Installations (MHIs) were invited to participate in the briefing and about 110 persons attended the briefing.

PEB Board member Er. Tong Chi Wai gave an overview on the development of the framework for registration of PE (Chemical) that would support the implementation of the new MHI regulations. Mr Go Heng Huat, Director of Major Hazards Department from Ministry of Manpower shared on the importance of the involvement of PE (Chemical) when the MHI regulations take effect in 2017.

Sep 2017: Safety Case Regime for MHI takes effect

In his opening speech of the MHI Symposium, Mr Sam Tan, Minister of State for Manpower, announced that the Safety Case regime would take effect on 1 September 2017 through the WSH (MHI) Regulations. There are three key elements in the Regulations, developed in consultation with the industry. First, rather than stipulating an absolute standard, MHIs are required to show that adequate, effective and reliable control measures are in place to reduce risks of major accidents to ‘as low as reasonably practicable’ or ALARP.

Sep 2017: Start of Safety Case Implementation Phase 1

Mar 2018: Start of Safety Case Implementation Phase 2

Sep 2018: Start of Safety Case Implementation Phase 3

Reference:

- The Singapore Safety Case Journey (https://www.wsh-institute.sg/files/wshi/upload/event/file/The%20Safety%20Case%20Journey%20for%20SG_Jaime%20Lim.pdf)

- Opening Speech at Major Hazards Installation Symposium 2016 (http://www.mom.gov.sg/newsroom/speeches/2016/1020-speech-by-mos-tan-at-major-hazards-installation-symposium-2016)